5 Things to Know: Mounting Springs Above Your Axle

Traditional trailers, caravans, and campers usually have springs mounted below the axle (often called “overslung” axles). However, some trailers in Australia are supplied with springs on top of the axle by default. For example, if you own a Jayco off-road caravan or camper, it’s very likely your axle is already like this. However, with more Australians exploring off-road, Couplemate™️ is often asked for assistance retrofitting their springs above the axle (aka an “underslung” axle).

If you are interested in this, there are five things you should know before you flip your trailer axle and springs.

Summary of Topics:

- You’ll get extra height and better ground clearance.

- Your U-bolts become even more critical (yes, it’s possible!).

- Your driving habits need to change for safety.

- Camber should be checked before you switch.

- You’ll need to change your axle pad location.

This is a sub-chapter in the Couplemate™ Technical Hub unit on Suspension (Leaf Spring & Beam).

1. Underslung axles will add height to your trailer and provide better ground clearance.

If you have ever wondered why people put their springs above the axle, this is your answer.

Let’s say you started with a 45mm axle, seven leaf springs (7mm thick leaves), and had 100mm in ground clearance. To work out your new ground clearance with a flipped axle, use the below calculation:

- (Spring Thickness x Number of Leaves + Axle Profile) + Current Clearance

In this example, it would look like the following:

- (7 x 7 + 45) + 100

- (49 + 45) + 100

- 94 + 100

- 194mm

You’ve gained 94mm in ground clearance! For many Australians, this is the easiest (and cheapest) option. However, as we’ll discuss, it’s more than just a simple flip.

2. U-Bolts become an even more critical part of your maintenance routine.

All experienced trailer and caravan owners know the importance of u-bolts and why they should never be overlooked.

Traditional spring-and-beam setups use two u-bolts and a fish plate to attach the spring to the axle. The “U” part fits over the axle and is then secured under your spring by a fish plate.

When torqued correctly, u-bolts will secure everything together so nothing moves.

Example of how an overslung trailer axle and spring are secured via U-Bolts.

As we know, an overslung axle means your axle is on top of your springs (as in the image above). If your u-bolts are loose, the axle will be between your spring and trailer chassis. However, on an underslung setup, your axle is below your springs.

One loose u-bolt and your axle (and more!) will be lost to the Bruce Highway.

This can be avoided by conducting regular maintenance, scheduling your trailer or caravan for service, and replacing your u-bolts when worn.

If you’re looking for tips on what to keep an eye on, you can read our holiday maintenance checklist here.

3. You must change your driving habits for the safety of yourself, your family, and other road users.

If you’re retrofitting an oversprung axle to your existing caravan/camper/trailer, you must accommodate the added height when towing. This means considering your trailer’s stability, such as its centre of gravity and dynamic forces from road conditions (like corrugation and potholes).

Before you hit the road, you’ll also need to look at the mechanical connection between your tow vehicle and trailer. When you raise your ride height, you also raise your drawbar and coupling height. If you were to hook up your trailer now, the coupling and drawbar would angle closer to the ground.

This matters because you’re putting excess weight on your tow ball.

Around 7-10% of your ATM should be distributed to your tow ball (e.g. 3500kg ATM = 350kg). This is why having a level of connection matters so much. You can achieve that optimum ball weight by spreading the load evenly from your trailer coupling and vehicle tow hitch.

If your hitch is made of hollow steel, has a welded ball mount, and hasn’t been tested inverted, we recommend upgrading to a cast product for safety.

Couplemate™ has a range of tow hitches that are built tough, to last, and can be safely inverted. An adjustable tow hitch will be your best option if you need an exact height and/or tow multiple trailers.

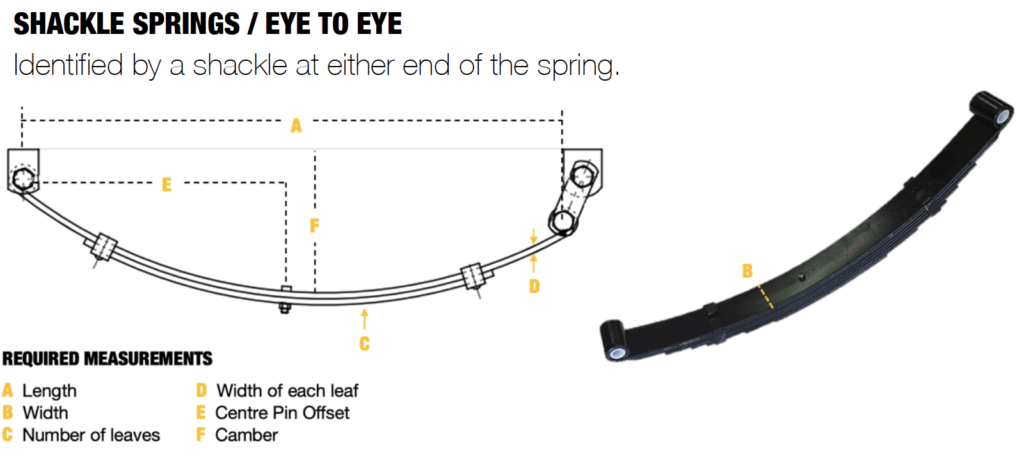

4. Check if your trailer springs are flat before switching.

There’s nothing worse than finding out you have flat springs after you’ve pulled your axle out.

If you’re reusing your current setup, we recommend checking your spring’s camber (i.e. the curve). This curve provides your trailer with suspension; without it, you’ll experience a lower ride height (and notice all the flaws of the Bruce Highway).

It’s normal for leaf springs to lose camber and flatten over time. So, if you’re going to the trouble of modifying your springs already, it’s worthwhile to invest in new springs to support your next journey.

See the expert guide to measuring your trailer springs here.

5. Leaf springs can snap on a flipped axle if the spring centre bolt is too long.

Traditional leaf springs are held together by a single bolt known as a spring centre bolt. All leaf springs must have this bolt, as they keep the individual leaves adequately spaced and aligned.

This is not an issue with underslung axles, as fish plates have a small hole in the centre to clear the spring centre bolt thread. If you look at our heavy-duty U-Bolt kit, you’ll quickly identify the hole we’re referring to.

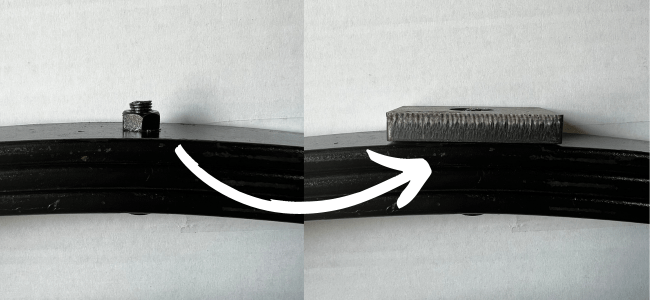

However, an underslung setup means your springs are on top of your axle. If the spring centre bolt encounters a solid surface (such as your axle), the thread can sheer off, resulting in leaves snapping and breaking.

The leaf spring snapped due to insufficient clearance of the spring centre bolt. The surface where the missing thread sheared off after contacting the solid steel axle under load can be seen.

This can be avoided by:

- Checking that axle pads have been welded correctly to your axle;

- Ensuring that your axle pad is thick enough;

- Removing excess thread from the spring centre bolt.

Couplemate™ provides axle pads that are 10mm thick in all of our u-bolt kits to help navigate this issue. If you find that 10mm still isn’t enough, you can safely cut off the excess thread that protrudes past the axle pad surface.

Here’s an example of a Couplemate™ 10mm axle pad on a flipped spring. The pad centre safely covers the spring centre bolt thread, which means it clears the axle.

Review a variety of 60mm Caravan Springs

- 5 Leaf x 60mm Jayco Leaf Spring – 705mm

- 6 Leaf x 60mm Jayco Leaf Spring – 705mm

- 7 Leaf x 60mm Jayco Leaf Spring – 705mm

- 6 Leaf x 60mm Offset Leaf Spring – 685mm – 576066

- 7 Leaf x 60mm Offset Leaf Spring – 685mm – 576067

And don’t forget, you have us!

Couplemate™ can help with replacement springs, trailer axles, maintenance kits, and the works.

Whether you’d prefer to contact us directly or browse our knowledge online, Couplemate™ is your friendly expert in towing, trailer, and caravan parts.

Hi There.

How are your experiences with your/ customer insurance companies considering you are changing the dynamics of how the factory fitted suspension works? i only ask as i just called my insurer and they stated that if i changed the spring setup different from how it was manufactured then they would not cover me in the event of an accident because of this? Possibly with an engineers report they may consider it but otherwise a definitive ‘no’. i can imagine an engineers report will cost me a fortune.

Does this sound right to you?

Thanks

Hi there, I have a light trailer 750 kgs ,slipper springs on top of square axle , one fish plate and square U bolts. Should the fish plate go on top of the spring or under the axle. If the fish plate goes on top of the spring should it be slight bent to match the curve of the spring. This will stop it from trying to straighten the spring when the u bolts are tensioned . Thanks