Trailer Axle Types: Overlay Axles

Overlay axles have changed, with companies and brands manufacturing them differently. This guide will help you understand this popular trailer axle type.

Outline of Topics:

- What is an overlay axle?

- Can you invert an overlay axle?

- What signs should you look out for?

- Is it easy to flip an overlay axle?

What is an Overlay Axle?

An overlay axle lowers your trailer chassis closer to the ground. This benefits boat trailers or horse floats, as a lower ground clearance improves access for boats and horses.

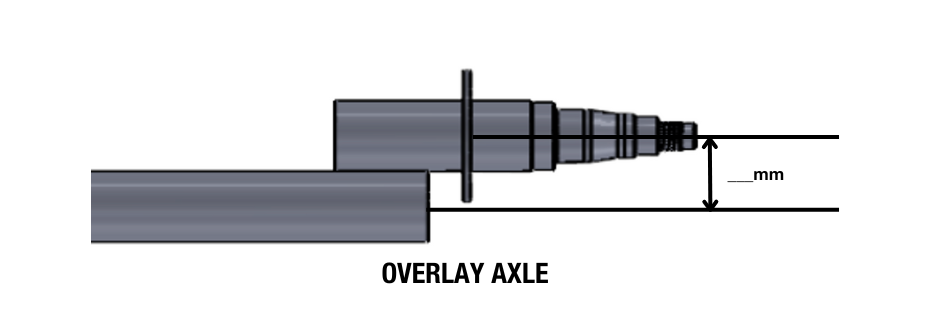

Couplemate™ Overlay Axles are made of Australian K1045 medium-carbon steel. By welding a stub axle on top of a regular beam, trailer manufacturers/owners can lower the chassis height by a distance equal to the span between the beam’s centre and the stub axle’s centre (see drawing below).

For example, a 50mm stub and a 50mm beam will result in a 50mm drop.

When Couplemate™ manufactures an Overlay Axle, our production team prefers to use round stud axles rather than square stub axles. Because of the cavity between the stub and the beam, our team can achieve a stronger, cleaner weld by beginning at the crevice and layering 3-4 welds.

Can you invert an Overlay Axle?

You may wish to flip your overlay axle for many reasons, though almost all of them pertain to gaining height. In the past, Couplemate™ has had customers who wanted to invert their axle due to a clearance issue with mudguards. They thought that, by adding height to their caravan, their tyres would stop scrubbing against the mudguards.

This is correct in theory but poses the question of whether overlay axles should be inverted.

To begin we will start with a brief explanation.

Traditionally, Overlays had 5mm of camber across the beam, meaning that inverting this axle would have disastrous results. Couplemate™ manufactures straight beam overlay axles, which would be far safer to invert than one with camber. Therein, it is difficult for Couplemate™ to recommend inverting overlay axles generally, as they’re not all manufactured the same.

There are a couple of features you can watch for. We highly recommend not inverting.

What signs should you look out for?

- Camber: Any camber other than zero is a safety issue

- Under-Slung: Axles located under the spring are a safety issue, as a damaged U-bolt can easily detach and cause your axle to become separated

- 1/2″ U-Bolts: A higher centre of gravity requires more clamping force to counteract the higher moving load forces.

- Thin Welds: Stub axle welds that are less than 50mm long.

- Hollow Beam: The core axle beam is made of hollow material, not solid.

- Missing Spacers: Axle spacers aren’t welded in between the spring and axle.

If your current overlay does not meet these conditions, you may be able to invert the axle.

Is it easy to flip an Overlay Axle?

No. It’s important to note that inverting an overlay axle is more than just a simple flip job; additional work and welding are involved.

Furthermore, the trailer driver must adjust their driving habits, as inverting your axle will result in the higher centre of gravity.

If you intend on flipping your axle, ensure that:

- Axle spacers are repositioned and welded to the axle.

- Park brakes are relocated.

- Top of the axle for 10” electrics.

- Bottom for 9” mechanical brakes.

- U-Bolts diameter is 16mm (5/8″) or more.

Overlay Axles and Articles

- 45mm Square Overlay Axles – Bare

- 50mm Square Overlay Axle Parallel

- 5 Things to Know: Mounting Springs Above Your Axle

- Intro to Wheel Backspace & Offset

- Intro to Wheel Backspace & Offset

0 Comments